Important Notes

For Corner Modeling:

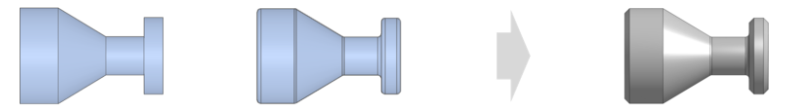

If corners are modeled with dimensions smaller than C/R0.5, they will be processed by default as C/R0.1~0.4.

If chamfers exceed C/R0.5 in the 3D model, they will be processed according to the 3D data.

It is not possible to specify “no chamfer” for these areas.

Additional Guidelines

For Outer Diameter with Specified Inner Corner R0:

A default clearance groove (depth of 0.5mm) will be machined.

If the cylindrical inner corner can have a default shape, it is recommended to select “Inner Corner R0~R0.4 or less.”

Sidebar

Recent Post

-

Large Language Models for Design and Manufacturing

November 19, 2024

-

-

Differences Between 3D Models and Finished Products

SH CAI|